SF-360E(320E)Drawer Type Single Facer

Structural features

Design speed: 150m / min

Effective width: 1800-2500mm

The main corrugating roller: ¢ 320mm (different according to different types), pressure roller ¢ 370mm, preheating roll ¢ 400mm

The negative pressure design with low heat loss makes the core paper uniformly pressed and attached to the surface of the corrugating roller, so that the corrugated can be better formed. Because the pressure is uniform, the top of the corrugated can be better coated with glue, so that the single-sided corrugated paper can fit better.

The whole set of corrugating rollers is sent into the machine and fixed on the base of the machine. Only one button switch is needed to quickly replace the corrugating roller.

The corrugated roller is made of 48crmo high-quality alloy steel. After heat treatment, the surface is treated with tungsten carbide after grinding, and the surface hardness is above hv1200 degrees.

The air bag control system with high stability is adopted for corrugated roller and pressure roller, and the air pressure control buffer effect is also available.

The glue feeding amount is controlled by electric adjustment, and the glue separating device is electric. The glue spreading system can operate independently when the main engine stops, so as to prevent the glue from drying up.

The mobile gluing system is convenient for cleaning and maintenance.

The simple operation control system, touch screen operation in terface, and color graphic display of operation status, function selection, fault indication, troubleshooting and parameter setting all show that the machine has complete functions, simple operation and humanization.

The built-in preset adjuster has a spray system to adjust the temperature and moisture content of the core paper.

High temperature grease is used for main and auxiliary corrugating roller and pressure roller bearing to ensure bearing life and smooth operation.

Technical parameters

| Working width | 1800-2500mm |

| Operation direction | left or right (determined according to customer's workshop) |

| Design speed | 150m / min |

| Temperature range | 160-200 ℃ |

| Gas source | 0.4-0.9mpa |

| Steam pressure | 0.8-1.3mpa |

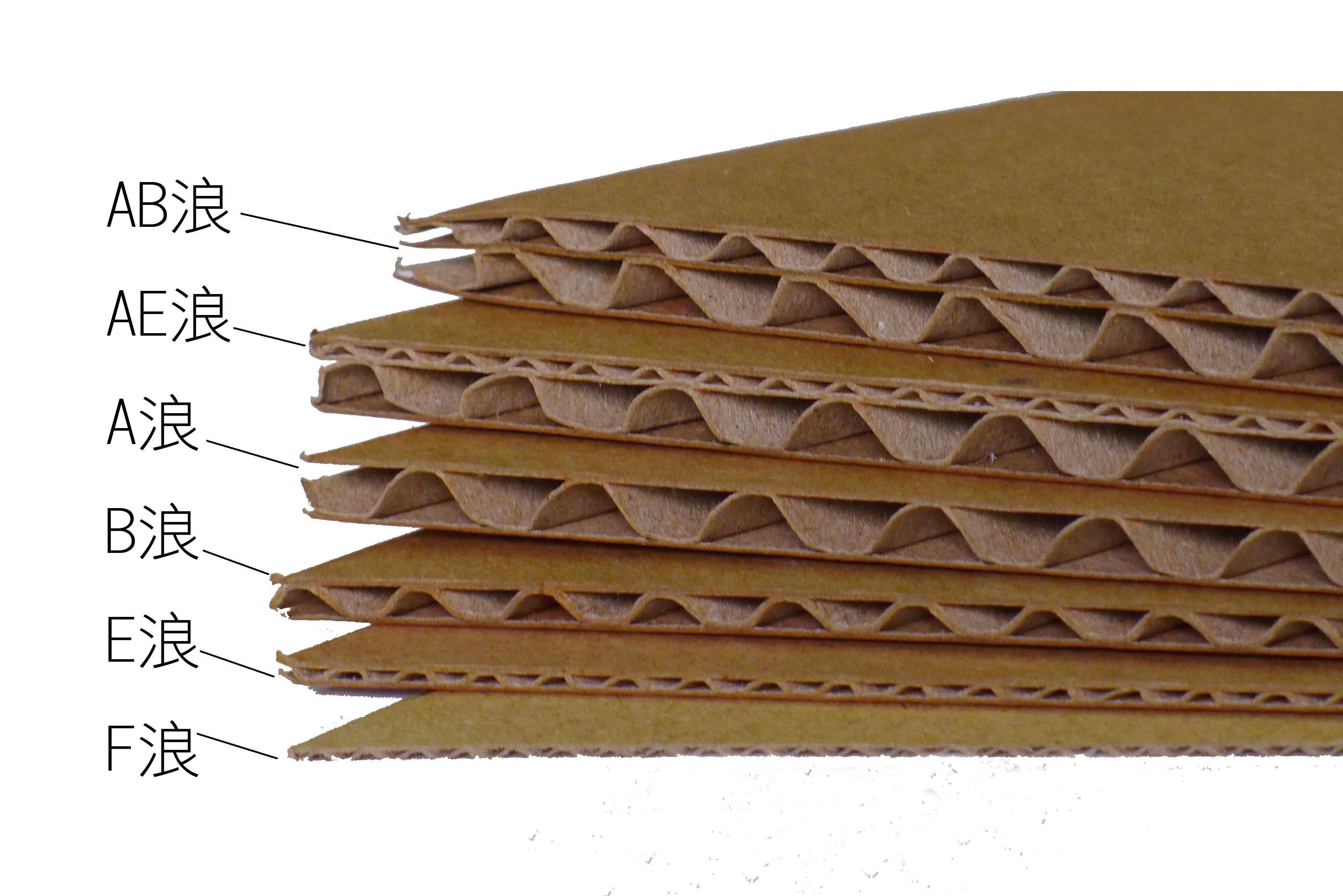

| Corrugated type | (UV type or uvv type) |

| The diameter of upper corrugating roller | ¢ 320mm |

| The diameter of pressure roller | ¢ 370mm |

| Wheel diameter | ¢ 269mm |

| The diameter of fixed paste roller | ¢ 153mm |

| The diameter of preheater | ¢ 400mm |

| Main variable frequency drive motor | 22kw |

| Suction motor | 11kw |

| mixing reducer | 100W |

| Adjustment motor | 200W * 2 |

| Motor of rubber pump | 2.2kw |

| Motor of glue coating part | 3.7KW |