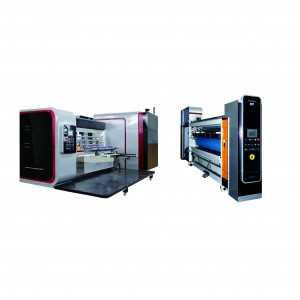

Factory made hot-sale China Automatic Printing Gluing Bundling Linkage Line Carton Box Making Machinery

The whole machine is in strict accordance with the high standard, high efficiency design, man-machine integration design concept, ful computer

centralized control.With a remote maintenance, breakdown self check, multiple protection functions such as alarm prompt.All electrical appliances, electronic components are choose the standards.

Stability of whole machine mobile unit layout, structure, concise:Simple operation, convenient maintenance.Transfer printing vacuum adsorption, servo control phase adjustment, to ensure the high quality, high points, high precision printing product requirements

Equipped with infrared drying system, UV glazing system.

Al the gear selects the high quality alloy steel 20 crmnt by carburzing, precision grinding to ensure long-erm transmission precision.Accuracy is

approximately equal to level 5-6)

Al roll axis selects the high quality steel, quenched and tempered treatment:Dynamic and static balance correction operation test twice, ensure the

equipmentrunning speed stable and reliable.

The whole machine selects the high quality materials and accessories.Wallboard, important parts adopt processing center production.

Options on a fixed all servo drive control system.

| Specifications | ||||

| Mode | 922(308) | 224(410) | 1428(480) | 1828(530) |

| Specifcatian | 2600 | 2800 | 3200 | 3200 |

| Max,machine speed (pes/min) | 360 | 260 | 218 | 180 |

| Max.feeding size (LxW) | 900×2250 | 1200×2450 | 1400×2850 | 1600×2850 |

| Min,feeding size(LxW) | 260×500 | 320x650 | 320×650 | 380×650 |

| Max.printing area (LxW) | 900×2200 | 1200×2400 | 400×2800 | 1600×2800 |

| Printing plate thickness | 7.2 | 7.2 | 7.2 | 7.2 |

| Max.die-cutting size | 900×2200 | 1200×2400 | 1400×2800 | 1600×2800 |

| Max.cardboard thickness | 2-11 | 2-11 | 2-11 | 2-11 |

| Voltage | 380-440 | 380-440 | 380-440 | 380-44 |

| Frequency | 50Hz-60H2 | 50Hz-60Hz | 50Hz-60Hz | 50Hz-60Hz |