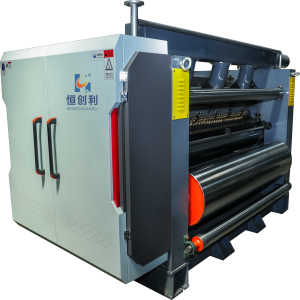

Sf-380 c adsorption type single side machine

| Effective width | 1800mm-2200mm |

| Operation direction | left or right(determined in accordance with customer plant) |

| Design speed | 180-200m/min |

| Temperature range | 160—200℃ |

| Steam pressure | 0.8-1.3 Mpa |

| Corrugated flute | UV type or UVV type |

| Corrugated roll diameter | up¢350mm down¢380mm |

| Pressure roll diameter | ¢385mm |

| Glue roller diameter | ¢264mm |

| Fixed paste roller | ¢140mm |

| Preheater diameter | ¢402mm |

| Main frequency drive motor | 22KW |

| Suction motor | 11KW |

| Glue reducer | 100W |

| Glue clearance motor | 250KW |

Structural features:

Cover suction structure, with high pressure strong fan, air suction and elimination device. Operating side hood fully enclosed construction.

The fan through the vacuum bellows will be corrugated paper adsorption in the corrugated roller approximately 180 degrees to form a negative pressure zone, to complete the forming of corrugated.

The width of the suction groove of the lower corrugated roll is 2.5mm, which can reduce the stripe trace of single corrugated board.

The transmission part adopts the independent gearbox universal joint transmission, isolating the vibration source, convenient maintenance, stable operation, the transmission gear adopts the oil-immersion lubrication mode, so that the gear is durable.

In the transmission bridge above the added tile roll lifting car, when needed, the use of the car will be tile roll assembly and pressure roll out, convenient and fast.

The coating roller unit adopts the overall external moving structure, the overall maintenance can be through the eccentric shaft conveyor device to the overall side of the coating unit out of the machine for maintenance, greatly saving the maintenance time, improve the work efficiency.

Equipped with spray humidifying device, so that the corrugated type to maintain good deformation stability, avoid dry crack, according to need through the valve control local area dry and wet.

Adopt automatic circulating glue supply system, double cylinder pneumatic glue device, with good buffering effect.

The gluing part adopts integral sliding plate structure. The surface of the gluing roller is engraved with 25 lines of pit mesh after fine grinding and plated with hard chromium.

the material of the upper and lower corrugated rolls are made of 48CrMO precision forging alloy steel. After adjusting and tempering, the whole teeth are polished and laser quenched and plated with hard chromium. The surface hardness is above HRC48 degrees.

The gap between the rubber roller and the lower corrugated roller adopts the worm gear reducer manual fine-tuning structure, the mutual parallelism is adjusted by the limit screw and the eccentric sleeve, easy to operate and intuitive.

The main power is driven by frequency conversion motor, the machine is controlled by Taiwan Delta PLC program, with low failure rate.

The wide width of the glue is adjusted electrically to adapt to the change of the width of the base paper.

The amount of glue is adjusted by electric, touch screen display and operation, and the gap of glue is transmitted through the encoder, with high accuracy.

The power and operation parts are equipped with safety protection net to ensure the safety of personnel during the operation of the machine.

Corrugated roller and pressure roller are pneumatic pressure device, stable work.

Core paper is equipped with steam humidification device.